36, WontFix, Modbus TCP seems to disregard.

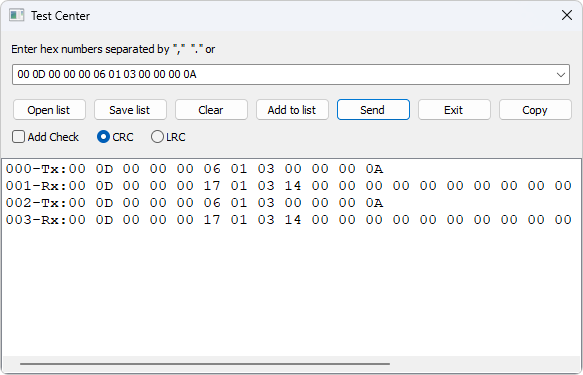

for the B&B USOPTL4 adapter, switch all 4 DIP switches to the ON position). 37, Invalid, Consistent checksum error when requesting read multiple registers Type-Defect Priority-Medium. The “echo” feature should be disabled (e.g. running the process) or if you do not want to poll any PLC connected to the card. Tuy nhin, nu cc bn ang lp trnh cho thit b modbus slave v khng c thit b master test th chng trnh Modbus Poll s l ng dng tuyt vi m phng ging. Data rate, Parity, and Error detection reference the settings on the. This problem can also be caused by enabling the “echo” feature of the USB/RS-485 adapter. Trong mt h thng mng Modbus, chng ta s c 2 thnh phn chnh l Modbus master v Modbus slave.The easiest type of adapter to use is one that converts to 2-wire (half-duplex) RS-485 and has an “automatic-send” feature (also called “auto-enable” or “auto turn-around”). To fix this, you need an RS-232 to RS-485 adapter. Is your Modbus master using an RS-232 port to interface with the meter? If so, this can appear to work in one direction (the master’s command reaches the meter) but it won’t work in both directions (the meter’s response never reaches the master or appears garbled) because the RS-485 interface on the WattNode meter is not compatible with the RS-232 interface on your Modbus master. Verify that the Modbus Poll application is receiving responses from the HMA (Tx is increasing) and that there are no communication errors being reported.But still I have error no.My Modbus master reports a CRC/checksum error or invalid response even though the WattNode ® meter’s Comm LED flashes green. I changed MB_Init block with SM0.1 and also check everything you told me. Also functionality test of that converter can be made for sure, no luck without it's functionality! Sry, don't work with that Modscan SW so no help here about functionality. You can also set some Delay time for sure, make tests. In case you not send or recv and some LED on converter is permanently on, this is problem with swapped wires on 485 side, you need change them. Do you have LED indications on that RS-485 to RS-232 converter? In not SEND/RECV time, that LEDs can be off, only if PC application send requests or PLC responds, the exact LED will be on. As I've sugested, this init block can be executed only once, on first scan - SM0.1 bit enable this block, look to help. Look pls again to help about MB_Init block.

0 kommentar(er)

0 kommentar(er)